Fire rated walls

faster stronger lower cost

XBeton AAC panels and blocks cut 30–50% of total wall costs by combining structure, insulation, fire and acoustics in one trade. Graphene dose packs elevate performance to UL-listed assemblies up to 6 hours, significant strength and permeability gains, and faster schedules.

- 30–50% total wall savings vs layered systems

- UL listed assemblies up to 6 hours

- 40% less labor, fewer trades, faster close-in

- Dose packs: stronger bonds, faster cures

- Withstands temps up to 6500°

- ~8000 PSI compressive strength

* By assembly and thickness. Verify with engineering and AHJ.

† Typical installed range material plus labor. Project conditions vary.

Why AAC with XBeton

Code-aligned, installer-friendly, and performance-dense: combine fire, structure, energy, acoustics and envelope control in one trade.

Faster build & lower cost

Lightweight units install fast with fewer trades and simpler sequencing for earlier dry-in and lower total wall cost.

Fire & life safety

Inorganic, non-combustible AAC with listed fire-rated assemblies; dose-pack finishes further enhance heat and permeability profiles.

Strength & durability

Engineered mass and reinforced options deliver reliable compressive and flexural performance for demanding applications.

Energy efficient

Thermal mass plus R-value help stabilize interiors and cut HVAC load across seasons.

Acoustic control

Dense, cellular structure reduces transmission for quieter multifamily, hospitality and education builds.

Moisture & mold resistant

Inorganic matrix with low permeability; dose packs support tighter envelopes while maintaining AAC breathability.

Proven and compliant systems

UL listed AAC assemblies plus CAD details and submittals. AHJ support included.

Strong and solid

Steel reinforced AAC with anti corrosion protection for demanding builds.

Quality and speed

Fewer trades and simpler sequencing mean faster dry in and fewer callbacks.

Fire resistant

Non combustible envelope with up to 6 hour rated assemblies.

Apartments

Faster installation and proven acoustic performance for multi family and mid rise.

Get Design Support

Commercial

Engineered strength and speed for offices, schools, hospitality and industrial.

Request ConsultationProducts

XBeton supplies structural AAC wall systems and proprietary dose-pack admixtures for finishes, bonds, and envelope control.

AAC Units

Blocks, panels and lintels manufactured under the XBeton brand. Structural, fire-rated and code-aligned wall systems.

- Load-bearing and non-load bearing blocks

- Panels for walls, shafts and floors

- Lintels for openings and spans

XBeton Dose Packs

Ready-to-use admixture packs that elevate AAC performance without special gear.

XBOND

Thin-set and panel adhesive for AAC assembly

XBASE

Leveling and structural repair for cavities, patching, and load-transfer

XRENDER

Graphene-reinforced stucco/render for AAC breathability

XFINISH

Interior/exterior finishes with UV, stain and thermal deflection

XSEAL

Joints, flashings, WRB and vapor control for tighter envelopes

AAC fire walls vs gypsum systems

Typical differences shown for planning. Confirm final assemblies and details with your engineer and AHJ.

| Criterion | AAC (U-series) | Gypsum shaftwall |

|---|---|---|

| Fire rating | Up to 6h* | 2–4h with layers |

| Assembly type | Single wythe | Multi layer |

| Inspections | Single path | Multiple |

| Wet area ready | Yes | Often no |

| Crew complexity | Fewer trades | More trades |

| Schedule risk | Lower | Higher |

* Assembly and thickness dependent. Verify with engineering.

Customer benefits vs. traditional wall systems

Consolidate fire, structure, energy and acoustics in one trade while improving resilience and reducing schedule risk.

| Criterion | XBeton AAC | Traditional (CMU/gypsum/stud) | Notes |

|---|---|---|---|

| Installed cost (total wall) | ↓ 30–50% | Baseline | Fewer trades, single inspection path |

| Labor input | ↓ ~40% | Higher | Larger units, faster staging |

| Fire rating | UL up to 6h* | 2–4h with layered systems | Assembly-dependent; engineer/AHJ verify |

| Thermal efficiency | High (R-value + mass) | Added layers required | Lower HVAC load over lifecycle |

| Acoustics (STC) | Typically 45–55 | Lower for 4" stud | Quieter multi-family & hospitality |

| Moisture & mold | Inorganic, low permeability† | Organic layers at risk | Dose packs further reduce permeability |

| Wind & seismic | High mass + ductility | Varies | Resilience in hurricanes/tornado zones |

| Schedule risk | Lower | Higher | Single wythe, fewer inspections |

| Lifecycle & finishes | Durable, low maintenance | More rework over time | Graphene-reinforced renders available |

* Fire rating varies by assembly and thickness. † Permeability reductions validated under ASTM C1202 with dose packs. Always confirm final assemblies with a licensed engineer and AHJ.

Standards & testing

XBeton AAC and dose packs are engineered to recognized U.S. standards and listed assembly families. Verify final design with a licensed engineer and your AHJ.

UL U-Series

Fire-rated wall assemblies up to 6 hours (assembly dependent).

ASTM C39 / C78

Compressive & flexural strength; dose packs show significant gains vs. controls.

ASTM C1202

Rapid chloride permeability; dose packs reduce permeability substantially.

ASTM C1693

AAC product specification and physical requirements.

TMS 402/602

Design & construction of masonry structures.

ACI guidance

Concrete & masonry practices relevant to AAC systems.

Summaries are provided for guidance only; reference official standards and current UL designs for submittals.

XBeton dose packs

Ready to use admixture packs that boost performance in thinset, stucco, repair and finishes. No special gear.

Thinset upgrade

- Higher compressive strength

- Better flexural performance

- Low permeability

Stucco and finish

- Cleaner bond to AAC

- Fast cure profile

- No special equipment

Repair and patch

- Field friendly

- Strong adhesion

- Consistent results

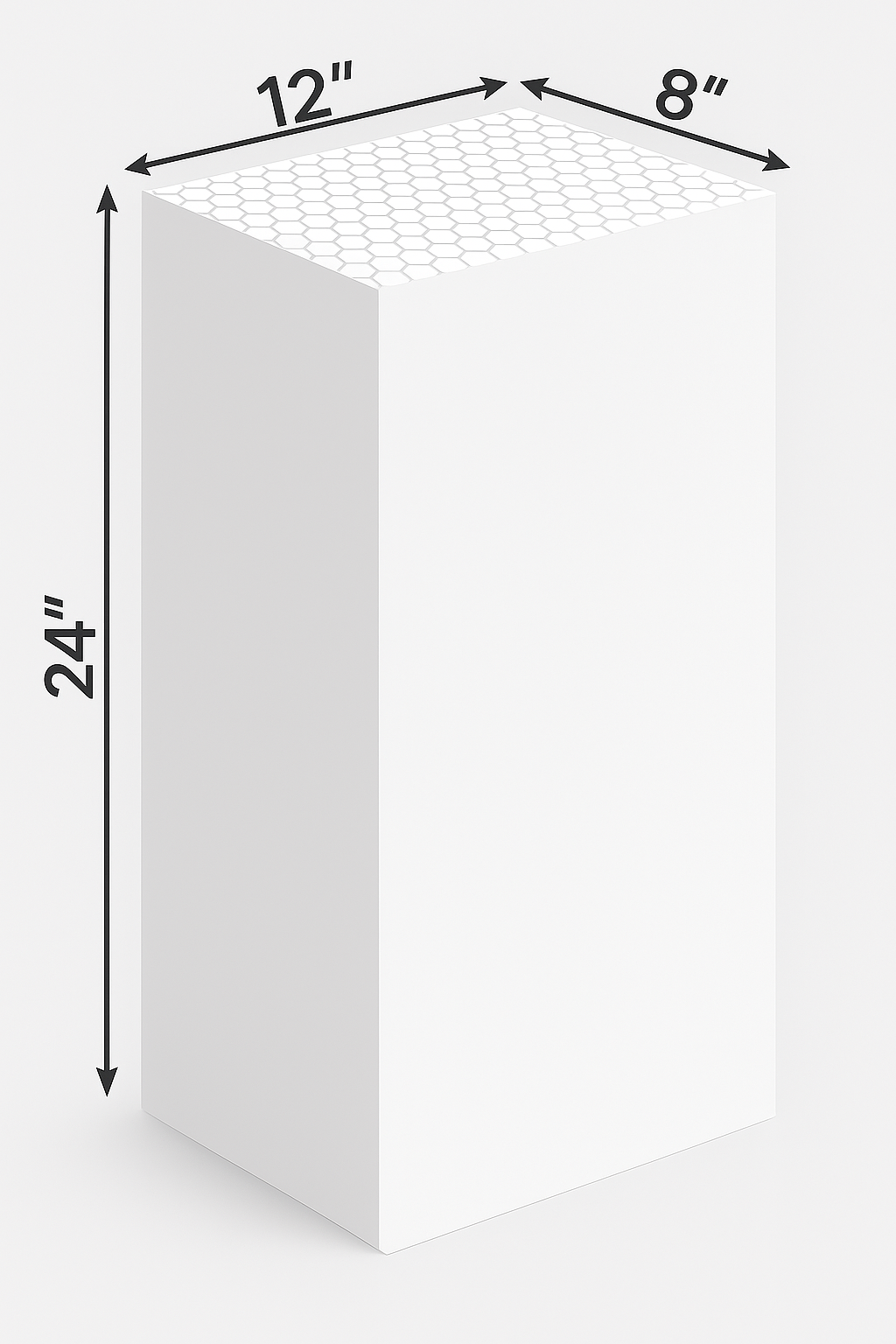

Xbeton Calculator

Quick estimate. Switch between Block and Panel products. Includes a 5% waste factor and adds overhead, safety, warranty, and profit on top.

Building Dimensions

Block size: 8×12×24 in

• ≤ 250 miles: $2 per block

• ≥ 251 miles: $4 per block

Miles are fetched via Google Distance Matrix. If the ZIP is invalid/unavailable, shipping is shown as $0 until resolved.

Results

Shipping is charged per block (flat): $2/block if destination ≤ 250 mi from 97702, else $4/block. Distance is computed via Google Distance Matrix. If the ZIP is invalid/unavailable, shipping is shown as $0 until resolved. Planning-grade only — confirm final quantities with a takeoff and your AHJ.

Request a quote

Send plans or a quick scope. We reply with assemblies, quantities and a schedule plan.

What to include

- Plan pages and wall schedules

- Required fire ratings and STC goals

- Approximate wall areas

- Site location and dates

- Any preferred assemblies or details

Download the Technical Brochure, UL letters, CAD details and install guides in Resources.